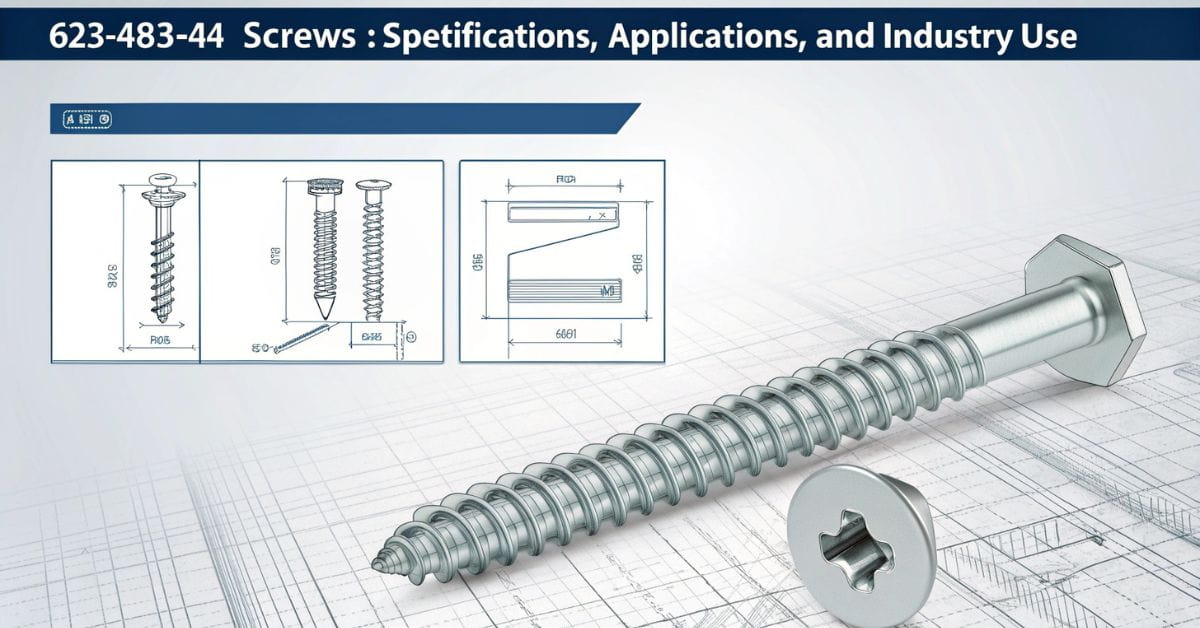

623-483-04 Screws: Specifications, Applications, and Industry Use!

When it comes to precision fastening solutions, few screws match the reliability and engineering quality of 623-483-04 screws. These screws are widely used across automotive, aerospace, construction, and electronics industries due to their high strength, durability, and excellent torque resistance. Their specialized six-lobe (Torx) design ensures enhanced grip, reducing the risk of stripping while offering superior load-bearing capacity.

If you’re in the market for high-performance fasteners, understanding the unique features, specifications, applications, and installation best practices of 623-483-04 screws is essential. In this guide, we’ll take a deep dive into everything you need to know.

Technical Specifications of 623-483-04 Screws – Know the Details

1. Size and Thread Pitch

Understanding the exact dimensions of 623-483-04 screws is essential for ensuring proper fitment and compatibility with different materials. These screws typically come in standard sizes, with a precisely machined thread pitch that prevents loosening under vibration or stress.

- Thread Type: Machine-threaded with fine or coarse options

- Diameter Range: Commonly between M2 to M12

- Length Variations: Available in multiple lengths for diverse applications

- Head Type: Torx (Six-Lobe) for improved torque control

2. Material Composition and Strength

The material of a screw plays a crucial role in its performance. 623-483-04 screws are often manufactured from:

- Stainless Steel (A2-70, A4-80) – Corrosion-resistant and durable

- Carbon Steel – Enhanced tensile strength, ideal for heavy loads

- Titanium – Lightweight and resistant to extreme temperatures

- Alloy Steel – Hardened for industrial-grade performance

3. Coating and Finishing Options

To increase lifespan and resistance to environmental factors, 623-483-04 screws are available with multiple coatings, including:

- Zinc Plating – Basic rust protection

- Black Oxide – Increases wear resistance and reduces glare

- Galvanized Finish – Excellent for outdoor or marine applications

- Nickel Coating – Used in electronics for conductivity and corrosion resistance

Read Also: Vietnam Digital Nomad Lifestyle Tips

Key Design Features and Benefits – Why They Stand Out

Six-Lobe (Torx) Head Design for Maximum Grip

The Torx head reduces cam-out, allowing higher torque application without stripping. This improves fastening efficiency and extends tool life while ensuring a secure grip for precise installations.

Precision Threading for Enhanced Fitment

The precisely engineered threads create a vibration-resistant fit, preventing loosening over time. This enhances durability, ensures even load distribution, and improves structural integrity.

High-Tensile Strength for Durability

Made from stainless steel, carbon steel, or alloy materials, these screws withstand extreme pressure. Their strength ensures long-lasting performance in high-stress applications like aerospace and automotive.

Corrosion-Resistant Coatings for Longevity

Protective coatings such as zinc plating, black oxide, and galvanized finishes prevent rust and wear. These coatings make the screws ideal for outdoor, industrial, and marine environments.

Compatibility with High-Torque Applications

Designed for high-pressure loads, these screws maintain structural integrity without deforming. Their secure fastening reduces loosening, improving safety and reliability in demanding applications.

Choosing these screws ensures strength, durability, and long-term fastening reliability.

Applications of 623-483-04 Screws – Where They Are Used

1. Automotive Industry – Ensuring Secure Fastening

In the automotive sector, 623-483-04 screws are widely used in:

- Engine assembly and suspension systems

- Chassis construction and brake system components

- Interior panels and dashboard fittings

Their high tensile strength and vibration resistance make them ideal for high-performance vehicles.

2. Aerospace and Aviation – High-Stress Applications

Aerospace engineering demands precision fasteners that can withstand:

- Extreme pressure and temperature fluctuations

- Corrosive environments and mechanical stress

- Heavy loads in aircraft assembly

623-483-04 screws are frequently used in aircraft fuselage, turbine engines, and landing gear systems.

3. Electronics and Circuit Boards – Small but Crucial

In the electronics industry, precision screws are essential for:

- Securing delicate PCB components

- Providing anti-static properties

Maintaining proper electrical conductivity

These screws ensure a secure fit without damaging fragile electronic parts.

4. Medical and Surgical Equipment – Precision Matters

Medical applications require hygienic, biocompatible fasteners, making stainless steel and titanium screws the preferred choice for:

- Surgical instruments

- MRI-compatible devices

- Orthopedic implants and prosthetics

Choosing the right screws for critical applications is essential for safety and durability.

Read Also: Play Free Browser Games on The Pizza Edition

Installation Guidelines and Torque Requirements – Get It Right

Use the Right Tools

A Torx screwdriver or bit works best for these screws because it gives a good grip. If you need to install many screws quickly, use a power drill with adjustable torque. A torque wrench helps apply the right pressure without making the screw too loose or too tight.

Torque Settings for Different Materials

Each material needs the right amount of force. For steel, use 4.5 Nm to 8 Nm to keep the screw tight. Softer metals like aluminum need 2 Nm to 4 Nm to avoid damage. For plastic, 1 Nm to 2 Nm is enough to prevent cracks.

How to Install the Screw

First, line up the screw with the hole. Press down gently and turn it in. Don’t use too much force. A torque wrench helps check if the screw is tight enough. Make sure it sits flat on the surface without going in too deep.

Stop Screws from Loosening

Screws can come loose over time, especially in moving parts. Using a little thread-locking glue helps them stay in place. Check screws now and then to make sure they are still tight. Store them in a dry place to avoid rust.

Corrosion Resistance and Maintenance – Extend Lifespan!

623-483-04 screws have special coatings like zinc plating, black oxide, and galvanized finishes to protect them from rust. These coatings help the screws last longer, even in wet or harsh conditions. Stainless steel screws are naturally rust-resistant, making them great for outdoor and marine use.

To keep screws in good shape, clean them and store them in a dry place. In damp areas, using an anti-rust spray can help protect them. Check screws regularly for rust or damage and replace any that are worn out. Taking care of screws helps them stay strong and last longer.

Read Also: About Poqimwazas Ltd – Origins, Growth & Industry Impact!

Future Trends and Innovations in 623-483-04 Screws – What’s Next?

Advanced Coating Technologies for Better Protection

New coating methods, like nano-coatings and self-healing finishes, are being developed to improve rust resistance. These coatings create a stronger barrier against moisture and chemicals, making screws last even longer in extreme conditions.

Stronger and Lighter Materials for Improved Performance

Manufacturers are working on new materials, such as titanium blends and high-strength alloys, to make screws both stronger and lighter. These materials help reduce weight in industries like aerospace and automotive without compromising durability.

Smart Screws with Embedded Sensors

Innovations in technology are leading to screws with tiny sensors inside. These smart screws can track tension, detect loosening, and send alerts for maintenance, improving safety and efficiency in construction and machinery.

Eco-Friendly and Sustainable Manufacturing

Companies are focusing on using recycled metals and eco-friendly production methods to reduce waste. More sustainable materials and processes will help create screws that are both strong and environmentally friendly.

FAQs – Answering Common Questions

Q1: What makes 623-483-04 screws different from other fasteners?

Torx head provides a strong grip, precision threading ensures a secure fit, and high-strength materials enhance durability for long-lasting performance.

Q2: Are these screws suitable for outdoor use?

Yes, especially when coated with galvanized or stainless steel finishes, which protect against rust and harsh weather conditions.

Q3: What industries use these screws the most?

They are widely used in automotive, aerospace, medical, electronics, and heavy machinery industries due to their strength and reliability.

Q4: How can I prevent screws from loosening over time?

Using thread-locking compounds and applying the correct torque settings during installation helps keep screws secure in high-vibration environments.

Q5: Where can I buy authentic 623-483-04 screws?

You can find them at trusted hardware stores, industrial fastener suppliers, and reputable online marketplaces.

Conclusion:

623-483-04 screws are designed for strength, precision, and long-term reliability. Their Torx head, high-quality materials, and corrosion-resistant coatings make them ideal for demanding applications in various industries. Proper installation, maintenance, and using the right torque settings ensure their durability and performance.

With advancements in materials, coatings, and smart technology, these screws will continue to evolve, offering even greater efficiency and reliability. Choosing the right screws and following best practices will help you achieve secure, long-lasting fastening solutions for any project. Investing in high-quality screws ensures strong and dependable results.

Read Also: