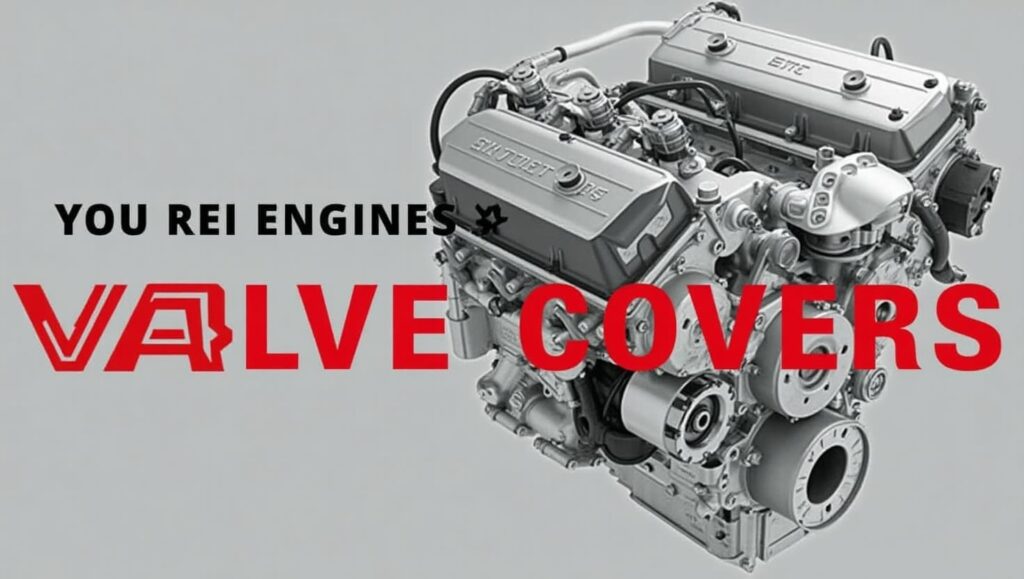

Does a 5.9 Valve Cover Fit N A 6.7 – Easy Installation Tips!

When I tried fitting a 5.9 valve cover on my 6.7 Cummins, I quickly realized the mounting points didn’t align perfectly, requiring custom modifications to make it work.

A 5.9 valve cover might fit on a 6.7 Cummins with some adjustments, but the design differences can make it tricky. It’s best to use a valve cover made for your engine to avoid issues. Check with a mechanic before making changes.

Thinking of replacing your Cummins valve cover? Before you dive in, learn whether a 5.9 valve cover truly fits a 6.7 and the crucial details you need to know.

Understanding Valve Covers in Diesel Engines – Discover Valve Cover Insights!

Valve covers are important parts of a diesel engine. They protect key components like the camshaft and rocker arms while stopping oil from leaking. By keeping everything inside the engine sealed and clean, they help the engine run smoothly.

In Cummins engines, the valve covers on the 5.9L and 6.7L models are different. These differences come from changes in engine size, design, and features like crankcase ventilation. It’s important to understand these differences if you’re thinking about swapping or replacing a valve cover.

Read also: Alyson H Belcourt Art – Blend of Heritage and Modernity 2025!

The 6.7L Cummins Valve Cover – Design, Components, and Key Features!

The 6.7L Cummins valve cover is a vital part of the engine, ensuring the protection of internal components and maintaining peak performance. Below is an overview of its design, key components, and features.

Design:

The valve cover for the 6.7L Cummins engine is engineered from durable materials such as aluminum or high-grade composites, capable of withstanding the intense heat and pressure inside the engine bay. The design includes:

- Shape and Structure: The valve cover is designed to fit precisely over the cylinder head, creating a tight seal that prevents oil leaks and protects the engine’s top end from contaminants.

- Mounting Points: It includes specific mounting points that align perfectly with the engine block, ensuring a secure fit using bolts. The design also accommodates the integration of various sensors and ventilation systems unique to the 6.7L model.

Components:

Key components of the 6.7L Cummins valve cover include:

- Gasket: A high-quality rubber or silicone gasket lines the perimeter of the valve cover, providing an effective seal to prevent oil from leaking out and keeping harmful contaminants out.

- Crankcase Ventilation System (CCV): Integrated into the valve cover, the CCV system helps manage engine emissions by rerouting crankcase gases back into the engine intake for combustion, reducing pollution.

- Electrical Connections: The valve cover houses various sensors, such as temperature and pressure sensors, which are essential for monitoring engine performance and ensuring optimal operation.

- Breather Assembly: This component allows for the proper ventilation of gases from the crankcase, preventing pressure buildup and maintaining engine efficiency.

Key Features:

The 6.7L Cummins valve cover boasts several advanced features that enhance its functionality and performance:

- Durability: Constructed from robust materials, the valve cover is built to resist corrosion, heat, and wear, ensuring a long lifespan even under harsh operating conditions.

- Integrated Systems: Unlike the 5.9L model, the 6.7L valve cover includes integrated systems such as the closed crankcase ventilation (CCV) and advanced sensor placements, which are crucial for modern engine management and emissions control.

- Heat Dissipation: The aluminum construction of the valve cover provides excellent heat dissipation, helping to maintain optimal engine temperatures and prevent overheating.

- Enhanced Sealing: Improved gasket designs and precision engineering ensure a superior seal, minimizing the risk of oil leaks and maintaining engine cleanliness.

- Aesthetic and Aftermarket Options: Many aftermarket valve covers for the 6.7L Cummins offer custom finishes and designs, allowing enthusiasts to enhance both the performance and appearance of their engine bay.

How does the dual-plate design improve engine performance?

The dual-plate design boosts engine performance by providing a stronger and more reliable seal. It evenly spreads pressure across the engine’s cylinder head, reducing the chance of oil leaks and ensuring the engine stays secure, even in tough conditions like high heat and pressure.

This design also improves crankcase ventilation, which helps control internal pressure and prevents harmful gases from building up. Better airflow means the engine runs smoother, lasts longer, and performs more efficiently. For drivers, this means fewer problems and a more dependable engine overall.

Read also: iZoneMedia360.com Entrepreneur – Boost Your Digital Presence In 2025!

Step-by-Step Installation of a Valve Cover on Cummins Engines – Get Your Valve Cover On!

Step 1: Gather Tools and Materials

Before starting, ensure you have all necessary tools and parts, including:

- A socket wrench and torque wrench.

- A new valve cover and gasket.

- Sealant (if required by the gasket manufacturer).

- Rags for cleaning.

Having everything ready saves time and ensures a smoother installation process.

Step 2: Prepare the Engine

- Allow the engine to cool completely to avoid injury.

- Clean the area around the valve cover to prevent dirt or debris from entering the engine.

This step is crucial for maintaining a clean environment and ensuring the new cover seals properly.

Step 3: Remove the Old Valve Cover

- Use the socket wrench to unscrew the bolts securing the old valve cover.

- Gently lift the cover off. If stuck, lightly tap with a rubber mallet to loosen it.

- Inspect and remove the old gasket, cleaning off any residue from the surface.

Step 4: Install the New Gasket

- Place the new gasket along the edge of the valve cover, ensuring proper alignment.

- If required, apply a thin layer of sealant as directed by the manufacturer.

- This step is vital for preventing oil leaks and ensuring a tight seal.

Step 5: Position and Secure the New Valve Cover

- Align the valve cover carefully over the cylinder head and gasket.

- Insert the bolts and tighten them lightly by hand to secure the cover.

- Use a torque wrench to tighten the bolts to the manufacturer’s specifications, avoiding over-tightening.

Step 6: Check for Leaks and Final Adjustments

- Start the engine and let it run for a few minutes to test for leaks.

- Inspect the area around the valve cover for any oil seepage.

- If leaks occur, recheck the gasket alignment and bolt torque.

- Once satisfied, clean your workspace and ensure no tools are left in the engine bay.

By following these steps in a systematic way, you can confidently replace the valve cover on your Cummins engine, ensuring proper function and durability.

Easy Maintenance Tips to Make Your Valve Cover and Gasket Last Longer!

To keep your valve cover and gasket in good shape, check for oil leaks regularly and clean the engine area to prevent dirt buildup. If you notice any cracks or signs of wear on the gasket, replace it as soon as possible to avoid oil leaks.

Using high-quality parts for replacements is important for durability. When tightening the bolts, make sure to follow the recommended torque settings to prevent over-tightening and damage to the gasket. These simple steps will help extend the life of your valve cover and gasket.

FAQs:

How can I spot a leaking valve cover gasket?

A leaking valve cover gasket may show up as oil residue around the edges of the cover, a noticeable burning oil smell, or a drop in engine oil levels.

What are the main causes of valve cover gasket failure?

High heat, exposure to engine chemicals, poor-quality gaskets, and improper installation are common factors that contribute to gasket failure.

Can a valve cover gasket leak cause long-term engine damage?

Yes, if left unchecked, a leaking gasket can cause oil to drip onto hot engine parts, leading to damage, reduced engine efficiency, or fire risk.

Is it dangerous to drive with a leaking valve cover gasket?

While it might not cause immediate breakdowns, it’s risky to drive with a leaking gasket because it could lead to engine damage or fire in extreme cases.

Is replacing a valve cover gasket a DIY job?

Replacing a valve cover gasket is typically a straightforward DIY task, but if you’re unfamiliar with engine components, it’s best to consult a mechanic or follow a step-by-step guide.

Conclusion:

To sum up, while a 5.9 valve cover may fit a 6.7 engine with some adjustments, it’s essential to understand the design differences and challenges, especially regarding sensors and emissions. Regular maintenance and timely gasket replacement are key to preventing leaks and ensuring long engine life.

Using high-quality parts and seeking professional advice when needed will help keep your engine running smoothly for years.